Methodology of process validation

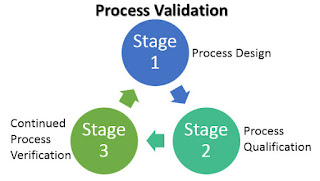

Process validation may be sub-categories into three phases:

1. process design

2. process qualification

3. Continuous process verification

|

Fig: Cycle of process validation |

1. Process design:

The objective of this phase is to design a process appropriate for routine commercial manufacturing that can consistently produce a produce that meets its quality attributes.

2. Process qualification:

During this phase, the process design is evaluated to determine the process is capable of reproducing the commercial manufacturing. This phase to be done in two stages:

A. Part-1: Design of the facility and qualification of the equipment and utilities.

B. Part-2: Process performance qualification (PPQ): cGMP complaints procedure must be followed during this stages. The need of training to be assessed prior to starting up of PPQ batches. Process for new product & existing products to be qualified based on current version of the process validation master plan (PVMP).

3. Continuous process verification:

The process parameters & quality attributes are monitoring under this phase continuously, at the level that had been established during process qualification phase.

Continuous process verification to be performed in steps as given below:-

ü Identification of CPP & CQA for Continuous process verification.

ü Continuous process verification throughout the life cycle of the product.

ü Annual product quality review.

Comments

Post a Comment